What if your smartwatch could melt into compost after a year of use—or your food label could dissolve in water after its job is done? That might sound like science fiction, but it’s quickly becoming reality thanks to a revolution in electronic design: recyclable thin-film electronics.

We live in a world where electronics are getting smarter, thinner, and more disposable. But this convenience comes with a heavy cost—e-waste. As our devices pile up in landfills, researchers and engineers are turning to new solutions that don’t just work better, but break down better too.

Here’s how recyclable thin-film electronics are setting a new standard for sustainable tech—and what it means for consumers like you.

What Are Thin-Film Electronics?

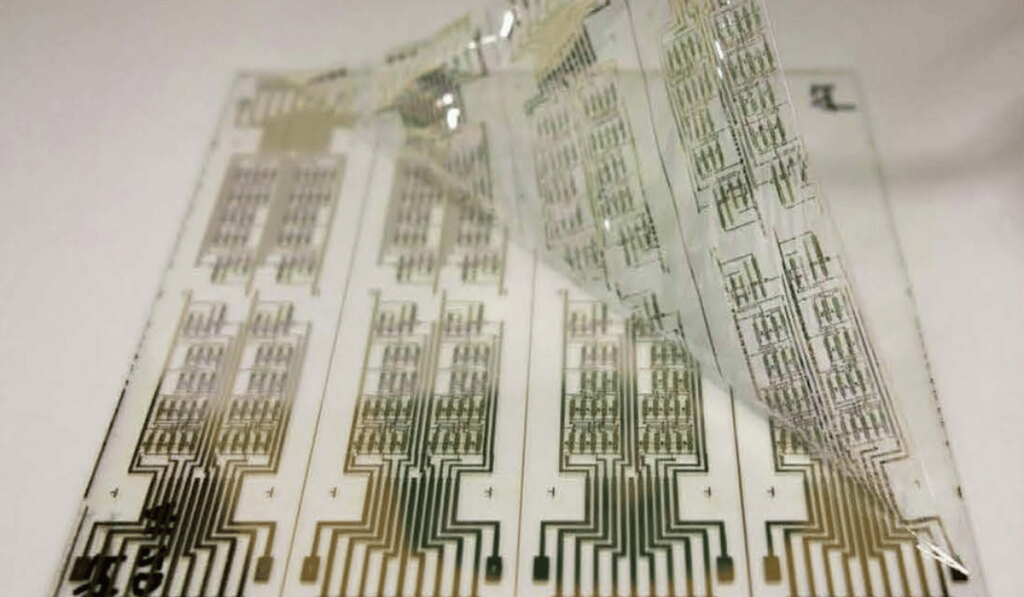

Imagine a circuit board that bends, stretches, or even wraps around your skin. Thin-film electronics are just that: ultra-light, flexible electronic circuits printed onto thin materials like plastic, paper, or biodegradable films.

They’re already used in:

- Smart packaging that can sense food freshness

- Wearables like fitness trackers and medical patches

- NFC/RFID tags for contactless payments and logistics

- Disposable sensors for diagnostics or environmental monitoring

But while these applications are growing fast, most of the devices are designed for short-term use. That means they’re quickly thrown away—and hardly ever recycled.

The Problem with Disposability

E-waste is growing faster than any other waste stream on Earth. According to recent estimates, over 59 million metric tons of it were generated globally in 2024.

Thin-film electronics, while small and lightweight, contribute to this problem because:

- They’re often made with non-recyclable plastics

- The metals inside are hard to recover

- They’re considered too “cheap” to process

In short, they’re convenient but environmentally costly. That’s why scientists are rethinking the way they’re made—from the ground up.

Green Materials Changing the Game

To make electronics recyclable—or even biodegradable—researchers are developing entirely new materials that are safe for both humans and the planet.

Substrates (the base layer):

- Cellulose from plants: compostable and abundant

- Silk fibroin: used in biomedical devices, naturally dissolves

- Polylactic acid (PLA): a bioplastic derived from corn or sugarcane

Conductive inks:

- Water-based silver inks: non-toxic and recoverable

- Carbon-based materials: like graphene or nanotubes

- Liquid metals: soft, flexible, and recyclable with simple processes

These materials make it possible to build electronics that perform well, but also degrade or disassemble without harming the environment.

Smarter Manufacturing, Smarter Recycling

One of the biggest breakthroughs in this space is how these devices are made—and unmade.

Instead of soldering components onto rigid boards, manufacturers are:

- Digitally printing entire circuits using inkjet or screen printing

- Assembling microchips at room temperature without toxic glue

- Designing circuits to fall apart in water or alcohol baths

Some devices are even fully recyclable in household conditions—imagine dropping a used electronic patch in a glass of isopropyl alcohol and watching it separate into reusable parts. That’s not just innovation; it’s sustainable design in action.

Real-World Examples

This isn’t just lab talk—several prototypes are already showing what’s possible:

- Stanford researchers created flexible biosensors printed on biodegradable films that dissolve after use.

- A team in South Korea developed recyclable smart packaging using conductive inks that decompose in alcohol.

- MIT scientists built a transistor on paper that fully dissolves in water, leaving behind no trace.

These examples prove that green tech doesn’t have to sacrifice performance. It just requires a smarter approach.

Why It Matters?

If adopted widely, recyclable thin-film electronics could significantly reduce e-waste while opening up exciting new markets.

Environmental wins:

- Less landfill waste from disposable devices

- No toxic materials leaching into the soil

- Reduced mining for rare earth elements

Economic opportunities:

- Lower disposal costs for manufacturers

- Easier recovery of valuable metals

- Growth of a circular electronics economy

It’s not just about saving the planet—it’s also about creating better, more sustainable business models.

The Roadblocks

Like all innovations, this one has challenges:

- Durability: Biodegradable components may not last long in harsh environments

- Cost: Green materials are still pricier than traditional plastics

- Scaling up: Manufacturing processes are still being optimized

- Consumer awareness: Most people don’t know this tech exists yet

But the momentum is building, and early adopters will play a key role in making recyclable electronics mainstream.

What Gizmogo Is Doing (and How You Can Help)

At Gizmogo, we’re already part of the solution.

Every day, we help people trade in old devices and keep electronics out of landfills. While recyclable thin-film tech is still evolving, we’re watching the space closely—and exploring ways to support it as it grows.

What you can do:

- Sell or recycle your old devices responsibly

- Buy less, but better—support companies using sustainable designs

- Spread the word about innovations like recyclable tech

Your choices matter—and they send a powerful message to manufacturers and policymakers.

Final Thoughts: A Greener Tech Future Is Thin, Smart, and Recyclable

Recyclable thin-film electronics aren’t just a trend. They’re a vision of how technology and sustainability can work together—from the smart patch on your arm to the package in your fridge.

As this field grows, one thing is clear: the future of electronics isn’t just about what they can do—it’s about what they leave behind.

Let’s choose tech that works for us and the planet.